THE evolution of the Holden as a racing sedan has been

little short of dramatic. Holden’s with

twice the manufacturer's horse-power are now common. Enthusiasts like Lou

Kingsley with bored-out,. Repco-headed Holden’s are talking of 140 b.h.p. But

the latest competition Holden is likely to have something like three times the

stock power — which, for the record. is 62 b.h.p. at 4,000 r.p.m. (nett) or 70

SAE horsepower at 4,000 r.p.m. (gross).

The most powerful Holden conversion to date has been carried

out by Merv Waggott of Waggott Engineering, a very active firm of general

engineers in Greenacre, a Sydney suburb.

The sedan belongs to Bill Thompson and there is talk of Jack

Myers piloting it in scratch races, with Bill at the wheel for handicap events.

For a completely new engine the power unit gave a quietly impressive account of

itself at the G.P. meeting at Bathurst. With

Jack Myers driving it gained third place in the scratch section of the second race.

| ||||

| Merv Waggot, the man who designed most of the engine | . |

Earlier, in practice, clutch trouble was experienced. During the race itself there was also

carburettor manifold trouble, and as the race went on the motor began to sound

less and less clean. Jack Myers reports

that on certain parts of the course on every lap, in exactly the same place,

the engine was starving for fuel and he was forced to drive accordingly. A fractured manifold was suspected and Jack

could not reach maximum speed. An engine

speed of 6,000 r.p.m. in top gear gave him a road speed of 111 m.p.h. However, maximum engine speed Is expected to

be around 7,000 r.p.m. , although a limit of 6,500 will be imposed on the

indirect gears. After the fuel check at

the end of the event the engine refused to start and Merv Waggott found that

petrol was spraying out of the carburettor union and the rear carburettor,

which was held on by the pipes and linkages alone.

A scorching hot thee liter ex-family car

with double overhead camshafts, sever bearing

crankshaft and a power to weight ration that

betters the Three PointFor Jaguar - can the go further?

Only two Stromberg carburet-tors were fitted for the

Bathurst event as the car was completed just in time for the meeting. For future

events, however, six Amals will be used. Merv Waggott, who has been responsible

for both the engine design and machining, is not a man given to guess work. For

this reason, he declines to estimate the likely power or speed of the engine.

But with the specifications before us our guess is that it will produce about

175 b.h.p. at 6,000 r.p.m.

Most believe that the evolution of bored-out special Holden

engines has reached its zenith. This

viewpoint is strengthened by the decision of Merv Waggott to lengthen the stroke

of the engine in his quest for more power. By doing this he has raised the capacity to

2995 c.c.. or nearly three litres.

A special seven bearing crankshaft has been made to

withstand the extra strain and the cylinder head is the well known Waggott

"double knocker" with twin overhead camshafts. The compression ratio is 9 to 1 and the

induction system will include six Amal carburettors.

The Waggott-Thompson Holden has a power to weight ratio of

about 150 b.h.p. per laden ton. This compares favourably with stock 3.4-litre

Jaguar, which has 145 b.h.p. per laden ton. But the engine is not the only

major modification. The stock gearbox has been replaced by a four-speed unit

from an XK 120; the clutch is a composite unit made up of two Holden clutch

plates, a Holden pressure plate.

Jaguar centres and a fabricated steel centre plate fitted

between the clutch plates. For the Bathurst meeting a standard pressure plate

was used with this special clutch. It failed, however, during the last lap of

practice. This was not apparent until Myers went to the line for the start of

the first sedan race. Bad vibration occurred and he could not select low gear—a

sign that the pressure plate springs had collapsed.

A new pressure plate was fitted for the second day's racing,

but Waggot Engineering is at presently modifying the clutch to give positive

driving location. The suspension remains

reason-ably standard, apart from stiffer coil springs at the front and more

powerful shock absorbers all round. Repco-Holden brakes will be fitted at the

front and possibly also at the rear. The three-litre engine capacity has been

obtained by boring out the cylinder bores to 81 mm. (roughly 3/16"

oversize) and lengthening the stroke to 96 mm., which is roughly x. longer than

normal. The seven bearing crankshaft has been designed and machined by Merv

Waggot himself. It was cut from solid 60 ton high tensile steel, It is fitted

to the Holden block by the use of an Ingenious "cage" which is bolted

to the lower half of the engine.

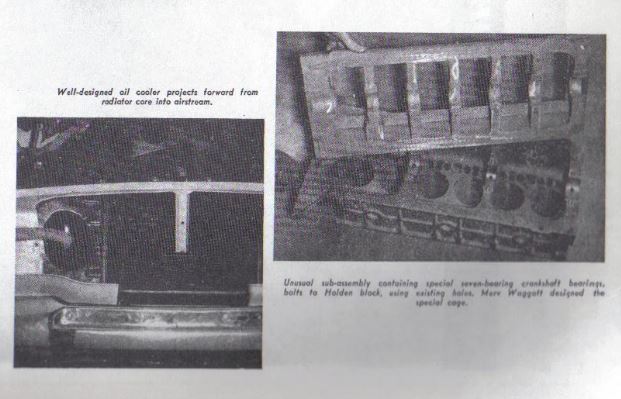

As our photograph shows, the cast iron cage has been

designed with seven bearing caps cast integrally. It is bolted to the block,

using the holes normally filled by the four bearing cap studs. The three

additional bearings are retained by caps which can be bolted to the cage itself.

This means that the crankshaft assembly

is clamped to the cage before it is bolted to the engine block. Initially,

standard connecting rods were used. Later special rods will be made in the

light of any lessons learned from the early operation of the new power unit, the

pistons have been specially cast and were machined by Waggott Engineering.

The contours of the camshaft are half way between semi and

full race and the engine will be reasonably flexible. The compression ratio is

9 to 1, so that pump fuel can be used to comply with sedan car regulations. A

standard oil pump is used, as past experience has shown that the gears of the

drive shaft are likely to shear if the oil pressure is raised. A full flow

Volks oil filter will be used. The ignition will be normal, apart from a Delco

twin breaker point distributor.

The cylinder head is similar to that used on Jack Myers' W.M

Cooper. The camshafts were machined from the solid by Waggott Engineering, but

the special valves were made by an outside firm. Maximum engine speed is expected

to be around 7,000 r.p.m., but a limit of 6,500 or even 6.000 will be amposed

for the indirect gears. Maximum speed will be governed by the choice of rear

axle ratio, but is likely to be around 120 m.p.h. Extra engine cooling has been

affected in two ways. First the radiator core has been thickened to help keep

the operating temperatures of the engine down, and secondly an oll radiator has

been added. So far this unusual Holden is still in the experimental stages. But

few men have had more experience with modified Holden engines than Merv Waggott,

Jack Myers and Bill Thompson are a formidable driving team. With this backing

the new car should prove unusually fast.

Article by Pedr Davis

No comments:

Post a Comment